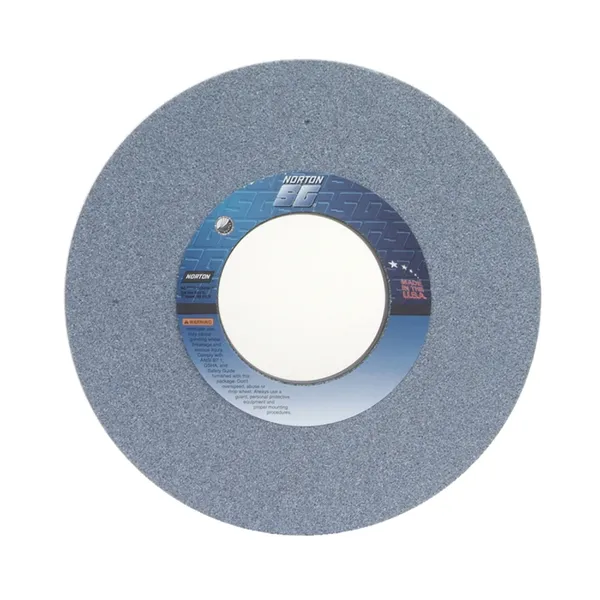

Norton 66253307025 3Sgp Straight Toolroom Wheel, 14 In Dia X 1-1/2 In Thk, 5 In Center Hole, 46 Grit, Ceramic Alumina/Friable Aluminum Oxide Abrasive

Details

Upc:662533070259

Mfpn: 66253307025

Specifications

Application

Item Features

- Exceptionally High Performance Ceramic Alumina And Friable Aluminum Oxide Abrasive Blend For Fast Stock Removal, Cool, Superior Cutting 3 To 5 Times More Life Than Aluminum Oxide Wheels

- Proven Porous Vitrified Bond, Especially Recommended For Toolroom And Surface Grinding On Medium To Wide Areas Of Contact And Heat Sensitive Materials

- Self-Sharpening Abrasive Minimizes Burn And Dressing, To Maximize Sharp Edge On Tools And Dies For Longer Life In Production

- Recommended For Narrow Area Of Contact, High Grinding Forces And Very Difficult To Grind Steels That Have A Very High Hardness Or Tensile Strength

- Best Choice For High Productivity, Low Total Per Part Grinding Cost

Use collapsible tabs for more detailed information that will help customers make a purchasing decision.

Ex: Shipping and return policies, size guides, and other common questions.